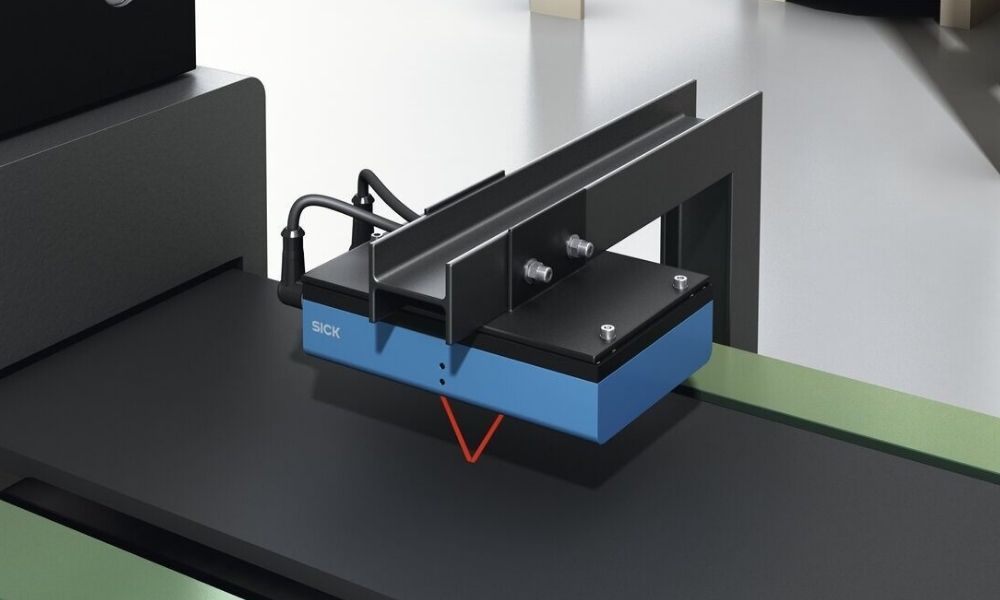

The SPEETEC® non-contact sensor for speed and length measurement, is a compact, affordable, eye-safe laser surface motion sensor, able to measure a wide range of continuous, web-fed or cut-to-length materials down to a resolution of 4 µm.

It is a non-contact measuring system that uses the laser Doppler principle to measure the speed and length of materials without the need for a scale or markers.

Its advantages over traditional measurement principles:

- Preserves the integrity of surfaces (optical principle having no physical contact with the object)

- Improves profitability (high measurement accuracy, reducing rejects in cut-to-length processes),

- Better productivity (no slippage possible allowing higher dynamics and increased process speed),

- Reduces downtime (due to wear of tactile measuring devices caused by abrasion),

- Easy to integrate (small size, easy to use for new machines or existing equipment)