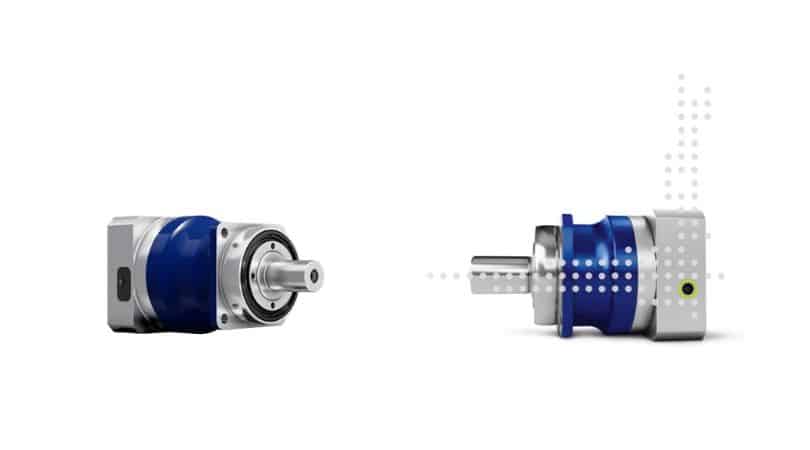

Wittenstein have launched the cynapse option on the alpha premium line range of gearboxes. These cynapse enabled gearboxes are capable of recording, storing and outputting temperatures, vibration, operating hours and mounting positions and processing them in integrated logic functions. Gearboxes with “cynapse” are identical to the existing models in terms of design, size and contour: instead of externally mounted parts, they ship with a sensor module that is elegantly integrated into the gearbox with a form-fit connection as well an electronic identification plate and an IO-Link interface.

Until now, gearboxes have been no good at communicating. The new smart variant alters this situation radically. The gearboxes have now “got something to say”: they are capable of recording and storing different parameters which impact on gearbox operation, and communicating them to automation systems as well as to all standard IIoT platforms.

This so-called “cynapse” functionality of the smart gearboxes – comprised of a sensor module, the data output using IO-Link and the resulting I4.0 connectivity – comes hand in hand with integrated logic functions for implementing customized tasks. For example, the actual and threshold values for temperatures and vibration can be compared directly in the smart gearbox, an alarm signaled if the high or low limit is exceeded and all events stored and documented.

The smart gearbox functionalities enables transparency, performance, reliability and availability, especially with critical axes. Critical operating states are detected sooner, so that the risk of damage to the gearbox and the drive train is minimized and expensive repairs or machine stoppages avoided.

Moreover, this gearbox data can be efficiently integrated into the maintenance and repair schedules for the entire machine or plant. WITTENSTEIN alpha gearboxes with “cynapse” consequently achieve a rapid return on investment.

The data from the smart gearboxes permits efficient process improvements – and the costs which result from damage far outweigh the comparatively modest markup for the integrated intelligence.

Contact us to discuss your Gearbox Applications.